Project Description

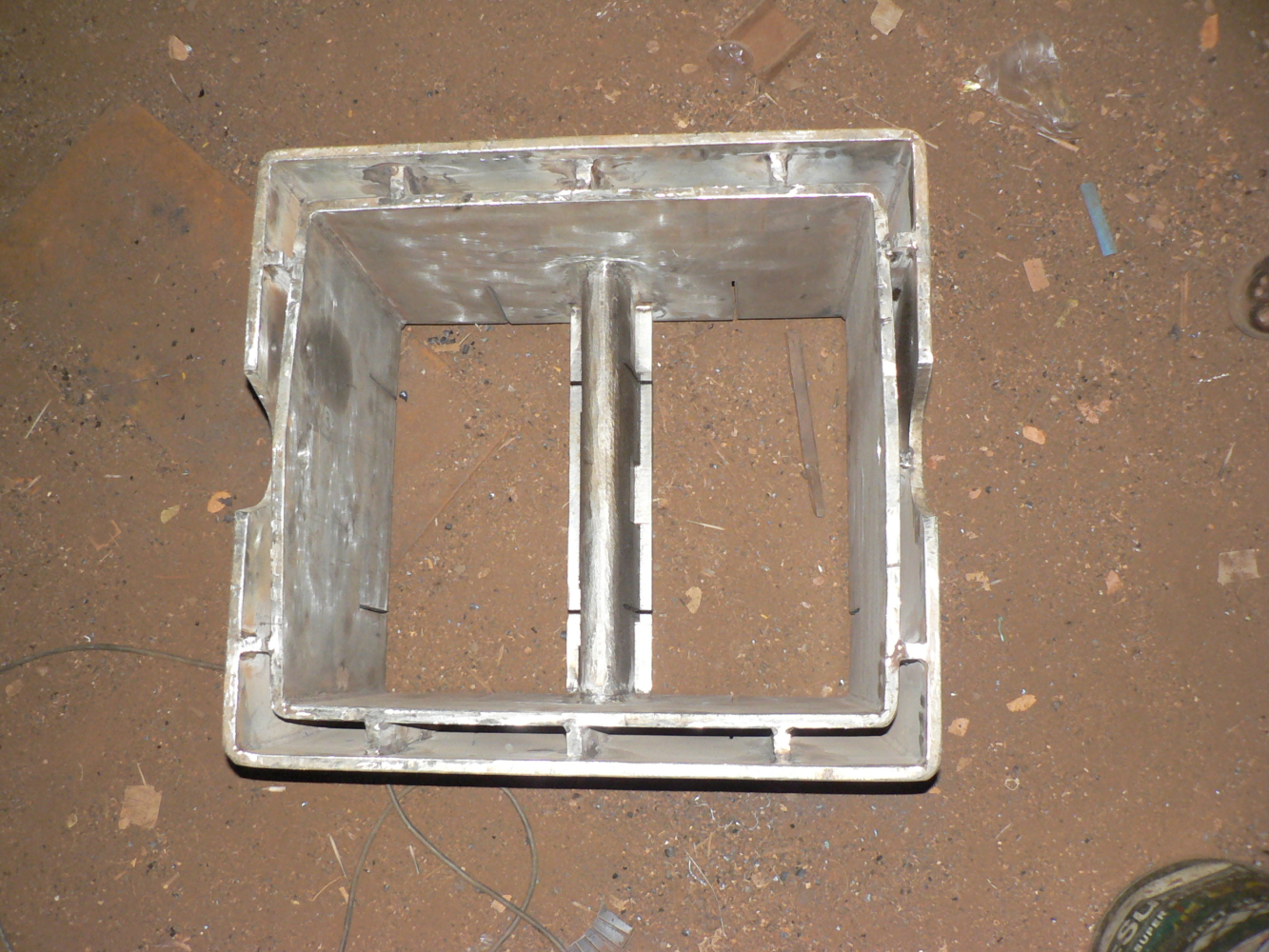

ADJUSTABLE COAL NOZZLE TIPS / COAL NOZZLE / COAL COMPARTMENTS (CONVENTIONAL /SPLIT / WIDE RANGE)

- CCE&CE manufactures complete Coal Compartment assemblies [Coal nozzle, Coal nozzle tips] for different sizes of coal-fired boilers.

- The coal compartment assembly is connected to the fuel inlet elbow at the wind box front directing fuel and transport air into the furnace.

- Major components of the compartment assembly are the stationary Coal Nozzle and tilting Nozzle Tip.

CCE&CE standard coal nozzle is with ceramic lining or without ceramic lining.

It is either fabricated that can be relined, reducing replacement costs, or machined from SG iron castings [ASTM A536 GR 65]

NOZZLE TIPS directs coal/air mix into the furnace and is the wear component in the coal firing system. They tilt up or down, directing air and fuel within the furnace, controlling fireball elevation, to aid heat rate control.

It is susceptible to high wear and erosion. A typical coal tip will warp, rupture, or both due to oxidation and erosion in the high temperature / harsh environment, they are subjected.

HARD FACING OF COAL NOZZLE TIPS: It is the deposition of wear-resistant matrix by welding to protect the high wear areas like splitter plates and leading edges.

Hard facing thickness can be 3mm – 6mm.

SALIENT FEATURES:

- Dimensionally accurate

- Designed for high quality and durability.

- Manufactured with Genuine raw material

- The genuine hard facing electrode is used for hard facing